- GST No. 27BDDPD7803F1ZV

Industrial Hoses

Leading Manufacturers, Exporters, Wholesaler, Retailer and Retailer of Hydraulic Hose (4SH), Hydraulic Hose (4SP), Hydraulic Hose (SAE-100 R1AT), Hydraulic Hose (SAE-100 R2AT), Food Suction & Discharge Hose, Chemical Suction & Discharge Hose, Composite Chemical Transfer Hose, PTFE Chemical Transfer Hose, Petroleum Transfer Hose, Plain Teflon Hose, Corrugated Teflon Hose and Stainless Steel Flexible Corrugated Hose from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Application | Air And Water |

| Tube | Oil Resisant Synthetic Rubber |

| Refinforcement | Four High Tensile Steel Wire Braid |

| Cove | Abrasion, Ozen and Hydrocarbon Resistant Synthetic Rubber |

| Temperature Range | -40*C to + 100*C |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Application | Air And Water |

| Tube | Oil Resisant Synthetic Rubber |

| Refinforcement | Four High Tensile Steel Wire Braid |

| Cove | Abrasion, Ozen and Hydrocarbon Resistant Synthetic Rubber |

| Temperature Range | -40*C to 100*C |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Application | Air And Water |

| Tube | Oil Resisant Synthetic Rubber |

| Refinforcement | One High Tensile Steel Wire Braid |

| Cove | Abrasion, Ozen and Hydrocarbon Resistant Synthetic Rubber |

| Temperature Range | -40*C to + 100*C |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Application | Air And Water |

| Tube | Oil Resisant Synthetic Rubber |

| Refinforcement | Two High Tensile Steel Wire Braid |

| Cove | Abrasion, Ozen and Hydrocarbon Resistant Synthetic Rubber |

| Temperature Range | -40*C to + 100*C |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Reinforcement | Multiple Plies Of Polyester Tire Cord With Helix Wire |

| Tube | Fda White Nitrile |

| Cover | Grey |

| Temperature Range | -40˚F to to +210˚F |

| Grade | Food Grade |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Reinforcement | Multiple Plies Of High Tensile Textile With Dual Helix |

| Tube | Clear Ultra High Molecular weight polyethylene |

| Cover | Green Abrasion Resistant Green Epdm (available in Blue, Yellow Black and Grey, White) |

| Temperature Range | -40˚F to to +210˚F |

| Grade | Superior |

A lightweight flexible chemical transfer hose designed for almost every common industrial chemical used in industry today. Nonstaining UHMW tube.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Inner Wire | Polypropylene - coated steel (P) |

| Inner Liner | Polypropylene Fabric |

| Hose Wall | Multiple layers of fabric/film/tubes |

| Cover | Black PVC coated polyester |

| Outer Wire | Galvanized Steel (G) |

| Temp Range | -40° F to +212°F (-40°C to +100°C) |

| Industry Standards | Complies with En13765 |

| Applications | Chemicals, Inks, Paints, Plant Processing, Rail Cars, Tank Trucks |

| Vacuun | Full |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Inner Wire | Stainless Steel (S) |

| Inner Liner | Polypropylene fabric (PTFF) |

| Hose Wall | Multiple layers of fabric Im/tubes |

| Cover | Red PVC coated polyester |

| Outer Wire | Stainless Steel (S) |

| Temp Range | -40° F to +212°F (-40.0 to +100°C) |

| Working Pressure | 250 PSI |

| Industry Standards | Complies with EN13765 |

| Applications | Chemicals, Inks, Paints, Pharmaceuticals, Plant Processing, Rail Cars, Tank Trucks |

| Vacuum | Full |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Inner Wire | Galvanized Steel (G) |

| Inner Liner | Polypropylene Fabric |

| Hose Wall | Multiple layers of fabric/film/tubes |

| Cover | Blue PVC-covered polyester |

| Outer Wire | Galvanized Steel (G) |

| Temp Range | 40° F to +212°F (-40°C to +100°C) |

| Industry Standards | Complies with AS1869 Class E & En13766 class A Type 1 |

| Applications | Marine, plant processing, rail car, ship-to-shore, tank truck service. |

| Vacuum | Full |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Teflon |

| Pattern | Plain |

| Temperature | -65˚F to 450˚ (-54˚C to 232˚C) |

Teflon is ideal material for flexible hose, to which a wire over-braid is added for exceller pressure ratings. Such hose gives extremely long life because its inner core has outstanding resistance to steam, chemicals, solvent, heat, pressure impulses, flexing, vibration, and age.

- Flexible : Hose of Teflon will stand up under severe conditions of continues flexing Chemical and vibration without failure from flex fatigue, inert Teflon creates a

- Resistant : Nearly “Universal” hose, capable of handling the broadest range of

- Applications. Except the molten alkali metals such as sodium and potassium, and flora chemicals such as chlorine trifloride, oxygen deflowered and fluorine gas.

- Temperature Ressistant : Even handles 350˚ F Steam alternating with cold water

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Flexible |

| Material | Teflon |

| Temperature | 65˚F to 400˚F (-54˚C to 204˚C) |

Corrugated transfer hose, is the most broadly applied a general-purpose workhorse found in undreds of chemicals transfer and food handling situations. Its present locations are as diverse as water purification systems, mercury transfer lines, and food processing equipment - delivering better to mixing kettels or sausage and other processed meats to packaging machines.

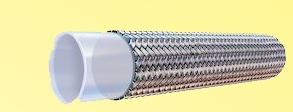

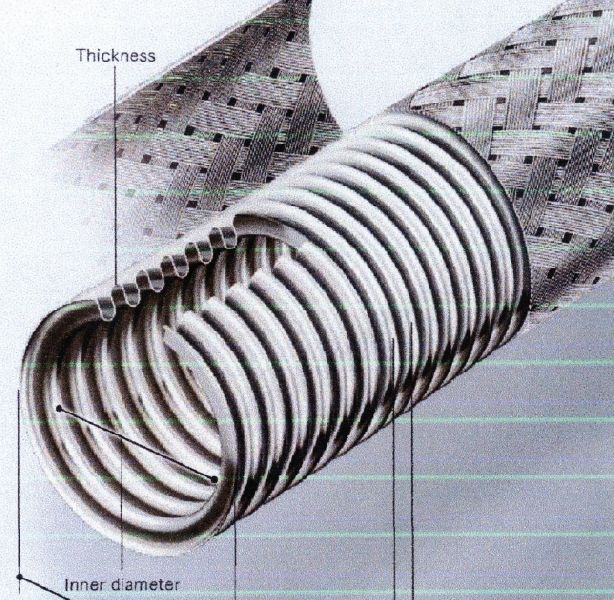

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Stainless Steel |

| Features | Corrosion Proof, Durable, Water Proof |

Type A (annular) flexible hoses are made by corrugating thin-walled stainless steel pipes. They are high-quality flexible hoses exposed to complete solution heat treatment. The corrugations are formed like individual rings which are not twisted under high pressure.

The hoses are highly flexible and have excellent strength, corrosion resistance and pressure resistance.

Braiding Process

To give corrugated hose the ability to withstand pressure, stainless steel wire is braided over the hose. Hoses may be single braided (one layer of braid) or double braided (two layers of braid) to achieve even greater working pressures. Braided braid is used on large-diameter hose.

Designing the proper braid for each type of corrugated hose requires sophisticated engineering to maintain the proper balance between the braid strength and the hose's flexibility. Hose Master's braid packages offer several advantages :

High Percentage Braid Coverage - Hose Master flexible hose has the highest percentage of braid coverage, yielding better cycle life and protection against damage to the hose.

Machine Braided Hose - Hose Master weaves the braid directly onto the hose, ensuring that the braid fits tightly against the hose, preventing potential hose deformation or squirm. Machine braided hose also offers repeatable performance and longer cycle life.