- GST No. 27BDDPD7803F1ZV

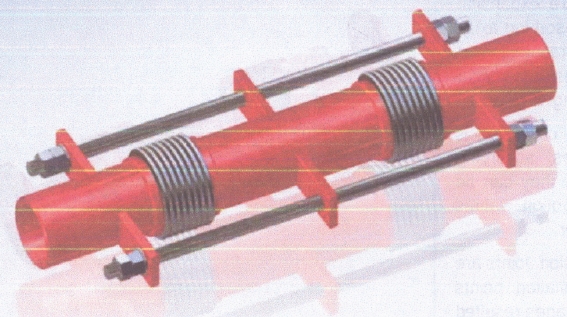

Expansion Joints

Leading Manufacturers, Exporters, Wholesaler, Retailer and Retailer of Axial Expansion Joints, Fabric Expansion Joints, Metal Bellow Expansion Joints, Rubber Expansion Joints, Seismic Expansion Joints and Universal Tied Expansion Joints from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Size | Standard |

| Material | Metal |

| Shape | Round, Square & Rectangle |

| Manufacture The | Metallic, Fabric and Rubber |

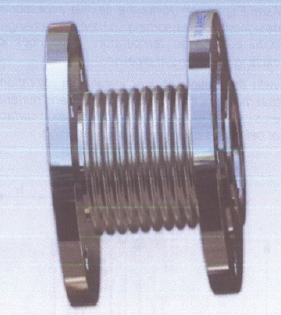

Axial Expansion Joints are flexible accessories designed for absorbing dimension changes occurred due to temperature differences or existing vibrations in pipelines. With the option of liner installation, vibrations that may result from high fluid flows and material erosion that erosive fluids may cause on surface of belloWS is prevented from happening.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Size | Standard |

| Material | Metal |

| Application | Industrial Use |

| Manufacture The | Metallic, Fabric and Rubber |

| Shape | Round, Square & Rectangle |

Fabric expansion joints perform a function of compensating for duct misalignment and duct thermal growth typical in power plants and other ducting systems. Fabric expansion joints are found wherever there is a need to convey hot media in low pressure applications such as "in flowing air” and “out flowing gas" in large combustion processes.

Fabric expansion joints can absorb larger movements than metal expansion joints and do so without spring loads. This is critical to limiting thermally induced stresses in ducting, ducting supports, and related equipment.

The chart shown above depicts the relationship of belt span, maximum compression and concurrent lateral movements. The maximum compression is a percentage of the available belt span (shown at the right end of the plot line). The wider the span, the more more capacity for compression. The lateral capacity is a function of the belt slack created with concurrent compression As the compression increases, more belt material is available to safely allow movement without overstressing the fabric material. In situations with large lateral movement and little compression, the joint can be installed pre-compressed to have more lateral capacity.

When in doubt, allow experienced U.S. Bellows engineers to help select the correct span for each particular application.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Bellows and Liner Materials | AISI 304 Stainless Steel (Optional : 316L, 316Ti, 309) |

| Connections | Carbon Steel (Optional: Stainless Steel) |

| Nominal Diameter | DN50 (2 |

| Operating Pressure | As Per Design or Client Requirement |

| Operating Temperature | As Per Design or Client Requirement |

| Connection Types | Floating Flanged, Fixed Flanged, Welding Neck |

| Design | According to the EJMA Standards |

| Manufacture The | Metallic, Fabric and Rubber |

| Shape | Round, Square & Rectangle |

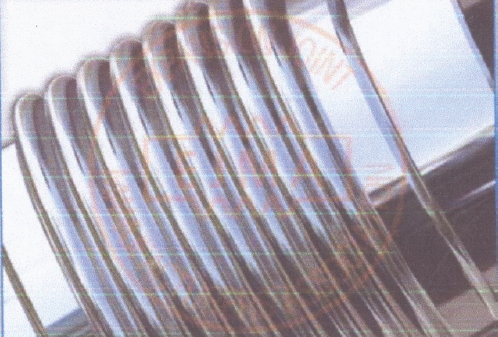

Expansion Joints are bellows flexible connection accessories used for absorbing thermal motions caused by ambient or transferring fluid temperature, angular motions originated from seismic events or land Subsidence and any vibrations occurs in installations.

Expansion Joints have stainless steel bellows (undulation) formed hydraulically as a main part and are used in many applications such as industry and buildings with addition of limit rods, cranks and liners.

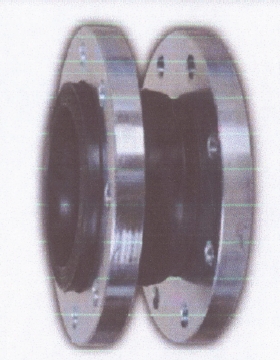

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Bellows | EPDM (Optional: NBR, NR, Viton) |

| Flanges | Carbon Steel (Optional: Staintess Steel) |

| Diameter | DN32 / DN1000 |

| Temperature | 100°C |

| Manufacture The | Metallic, Fabric and Rubber |

| Shape | Round, Square & Rectangle |

Rubber Expansion Joints are installation accessories that can absorb axial, lateral and angular motions. Rubber Expansion Joints are consist of rubber main body, steel wire and nylon cord reinforced special synthetic rubber.

Main advantages are easiness of installation with floating flanges, vibration and sound absorption, installation without additional need for seals.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Size | Standard |

| Material | Metal |

| Manufacture The | Metallic, Fabric and Rubber |

| Shape | Round, Square & Rectangle |

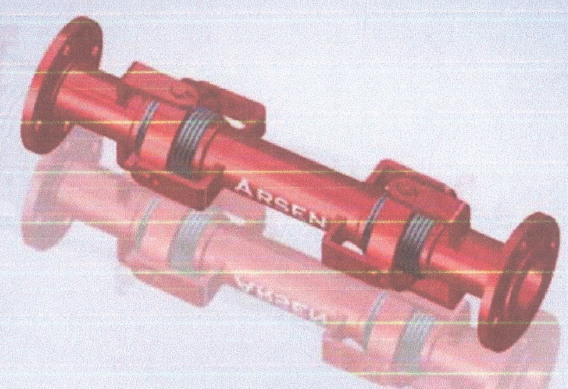

Seismic Expansion Joints are expansion joints with cranks used for absorbing axial, lateral and angular motions resulted from seismic motions (earthquakes) that occur in points with a risk of breaking.

When requested absorbing capability is higher than standard values, according to application they are used, they can be designed specifically for motion values calculated by project engineer. Gimbal Type Seismic Expansion Joints are for protecting pipeline installation points and prevents them from damages resulted from seismic motions or subsidence.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Size | Standard |

| Material | Metal |

| Manufacture The | Metallic, Fabric and Rubber |

| Shape | Round, Square & Rectangle |

Universal Tied Expansion Joints are used in buildings with different construction foundations. They are installation accessories in order to absorb large lateral motions resulted from subsidence and ground motion. Thus, pipelines are prevented from damage after possible motions.